6-PAK Elephants

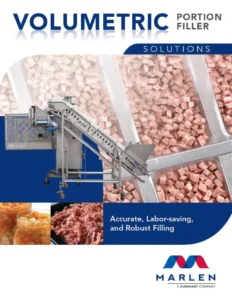

CircFood’s Carruthers Six-Station Rotary Volumetric Filler is designed for filling food products into cans, jars, cups or form-fill-seal pockets. With fill weights up to 1.5 lbs per portion, our 6-PAK filler is ideal for filling hot or cold shredded meats or freshly diced food products. CircFood’s PAK series fillers offer minimal fines with little product damage, preserving product integrity and appearance in the package. Reduce labor costs associated with hand filling, and shift manpower to other areas.

- Product Family: Filling

Features

- Six-station automated rotary volumetric filler for portioning ‘difficult to fill’ products like cooked and fresh beef, poultry, pork, seafood, and vegetables

- Designed to handle side or fill feed applications

- Target fill sonic sensors assure maximum yields by achieving fill weight accuracy within each fill station

- Patented slide-fill process surrounds over-sized and random shaped product while portioning to reduce damage

- Designed to eliminate the need for moisture. Products flow gently without adding liquid which allows seasonings to stay on, assuring better quality in taste and appearance

- Products placed accurately. Portion shape, size and placement are all defined to keep seals and containers clean

- Positively fed through the machine, this means no bridging as it does not rely on vacuum or gravity

- Designed and constructed to maximize uptime through easy operation and maintenance

- 6-PAK Filler is easy to clean

- Adjust fill weights “On the Fly.” Adjustments can be made at start-up or in production. No wasted time or product “dialing in”

- Fully mechanical design using a single motor which makes troubleshooting easier

- Made in the USA

The 6-PAK rotary volumetric filler is available in many portioning configurations to suit your container line, whether continuous or indexing, single or multi-lane, trays, pouches, thermoform packages, jars, cups, cans.

Rigid Containers (Cans/Jars)

- Containers fed through filler

- Bottom fill capability for smallmouth containers

- Double pass capability for large or tall portions

- Ability to compact portions in container for headspace

Single-Lane Target Depositing

- Designed for continuous moving ‘entree’ and ‘ready meal’ assembly lines at low to high speeds

- Filler synchronized to moving containers

- Containers such as trays, bowls, tortillas

- Portioning pockets synchronize and move with container during discharge to ensure smooth transfer and accurate placement

- Adjustable product placement in both directions

Multi-Lane Target Depositing

- Designed for indexing Thermoform/rollstock or multi-lane tray/cup sealing machines

- Indexing mode for filler

- Simple electronic handshake signal with packaging machine

- Cantilevered design; no hardware needs to be attached to packaging machine

Vertical Pouches

- Pre-made pouches or bags

- Filler directly interfaced to pouch handling system for smooth transfer

- Simplex or duplex mode

Specs

Fill Stations: 6

Slide or Bowl Fill: Slide and Bowl

Maximum Portion Diameter: 3.875″ (98.4 mm) x 5″ H (127 mm)

Maximum Portion Weight: 1.5 lbs (0.68 kg)

Industry Applications

Documents/Resources

Videos

6-PACK Filler Promo